Offer

Camprofile gaskets

Basic specification:

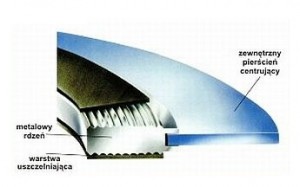

Camprofile consists of metallic core, usually made of stainless steel, with a double-side grooved profile and sealing layers.Gaskets can be used for pressures up to 25 MPa and temperatures up to 1000 °C.Gaskets are applicable for numerous applications for all flange types (DIN, ASTM, EN, ČSN), its solid structure ensures uniform pressure distribution on the groove profile,

Camprofile consists of metallic core, usually made of stainless steel, with a double-side grooved profile and sealing layers.Gaskets can be used for pressures up to 25 MPa and temperatures up to 1000 °C.Gaskets are applicable for numerous applications for all flange types (DIN, ASTM, EN, ČSN), its solid structure ensures uniform pressure distribution on the groove profile,

High reliability during temperature and pressure fluctuation.

Opportunity of re-use of metal core.

Construction:

Parallel:

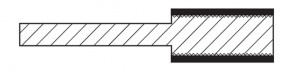

M18L

Gasket with parallel core with fixed guide ring

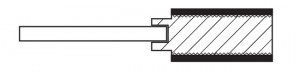

M20 L

Gasket with parallel core especially for flanges for groove and socket as well as tongue and groove flanges.

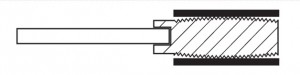

M21LM

Camprofile with parallel core and free (floating) guide ring.

Convex:

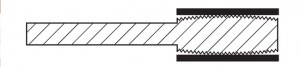

M38L

Camprofile with convex core with fixed guide ring.

M40L

Gasket with parallel core especially for flanges for groove and socket as well as tongue and groove flanges

M41LM

Camprofile with parallel core and free (floating) guide ring

Standard metal core materials:

| AISI ASTM | DIN material no | DIN specification | Hardness HB | Temperatura (°C)min. max. | Density(g/m3) |

| Carbon steel | 1.0038 | RSt.37.2 CS | 100-130 | -40 +500 | 7,85 |

| 321 | 1.4541 | X10CrNiTi 189 | 130-190 | -250 +550 | 7,9 |

| 304L | 1.4306 | X2CrNi 189 | 130-190 | -250 +550 | 7,9 |

| 309 | 1.4828 | X15CrNiSi 2012 | 130-190 | -100 +1000 | 7,9 |

| 316Ti | 1.4571 | X10CrNiMoTi 1810 | 130-190 | -100 +550 | 7,8 |

| 316L | 1.4404 | X2CrNiMo 1810 | 130-190 | -100 +550 | 7,9 |

Recommended core thickness:

3 or 4 mm (new application)

Recommended sealing thickness 2×0.5 mm; 2×1 mm:

Expanded graphite: -200 +550

PTFE: -200 +250

CSF: -40 +250

Recommended flange surface roughness:

Ra=3,2 do 6,3 (μm)

“Q” impact pressure table:

| Sealing layer | „Q” impact pressure (N/msq m) in temperature of +20°C | ||

| min. | perm. | max. | |

| Expanded graphite | 20 | 90 | 400 |

| PTFE | 20 | 90 | 400 |

| CSF | 20 | 125 | 400 |